1. Friction Coefficient

The coefficient of friction is a measurement of frictional force between two surfaces. It is an index of friction behavior of the material. Film friction coefficient depends on the superficial adhesivity (surface tension and crystallinity), additive (smooth agent, pigment, etc.), and surface polishing. Friction coefficient should be controlled strictly in the following operational sequence: film crossing free roller, bags of shaping, products twine and the stacking of package and other containers. Besides the internal variable factors, environmental factors (such as running speed, temperature, static accumulate, and humidity of the machine) can also influence the test result of friction coefficient.

2. Influence of Temperature on Friction Coefficient

The state change of molecule motion of high polymer is called laxation according to the view of dynamics. The rising of temperature can improve heat movement ability of moving units on the one hand. On the other hand, because of thermal expansion, it increases molecule distance. Namely the internal freedom volume within the high polymer increases, which can increase activity space of moving unit, accelerate molecule movement, shorten relaxation time and expedite relaxation process. Following the relaxation of high polymer, its thermodynamics nature, viscoplasticity and other physical properties will also change dramatically. As one of the most frequently used indexes of mechanics, friction coefficient can also be influenced by the increase of temperature. Generally speaking, with the rising of environment temperature, surface friction coefficient of the material will have certain change, but changing amount will differ from material to material.

3. Temperature Rising Experiment

To verify the influence of temperature fluctuation on friction coefficient, the friction coefficient of several groups of material with certain representativeness are tested under different temperature. Detailed testing information and testing results are listed below:

Specimen: PC film, aluminum foil complex film

Instrument: Labthink FPT-F1friction coefficient /peel tester

Testing temperature: room temperature~90.0 °C

Testing data:

Table 1. Friction Testing Data of PC Film

| Testing temperature °C | Coefficient of static friction mean1 | Coefficient of kinetic friction mean1 |

|---|---|---|

| 32.1 | 0.285 | 0.244 |

| 45.5 | 0.336 | 0.212 |

| 62.0 | 0.387 | 0.319 |

| 74.1 | 0.435 2 | 0.322 2 |

| 87.5 | 0.433 2 | 0.300 2 |

Note1: testing data are mean value of several groups

2: phenomenon of stick-slip

Table 2: Friction testing data of Aluminum Foil Film

| Test Temperature °C | Coefficient of static friction mean1 | coefficient of kinetic friction mean1 |

|---|---|---|

| 29.6 | 0.314 | 0.239 |

| 46.2 | 0.355 | 0.277 |

| 74.3 | 0.343 2 | 0.253 2 |

| 89.5 | 0.429 2 | 0.241 2 |

Note 1: testing data are mean value of several groups

2: phenomenon of stick-slip

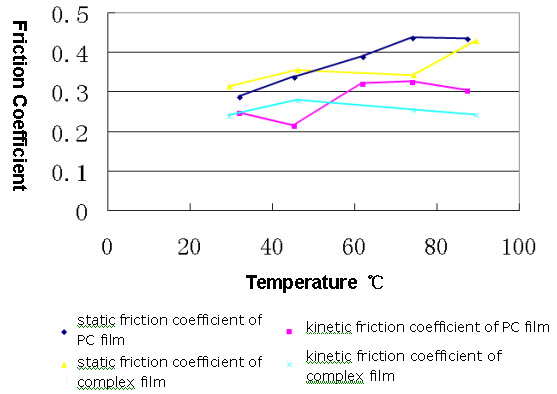

Data curve with the increase of temperature is shown as fig. 1:

Fig 1. the rising of temperature obviously influenced friction coefficient of material

From fig 1 we can see that the rising of temperature has obviously influenced friction coefficient of material. But to different specimen, with the rising of temperature, the effects of influence are different. And to the same specimen, the variation tendency of kinetic friction coefficient will most likely be different from that of static friction coefficient. For example, to PC film, the growth trend for coefficient of static friction with the temperature rising is rather steady. But the variation tendency for coefficient of the kinetic friction is very great. However, the whole variation trend for kinetic friction coefficient also increases. As to aluminum foil compound film, growth trend of friction coefficient is not as obvious as that of PC film. And its coefficient of kinetic friction remains almost stable with the rising of temperature. One thing needs to be noted here is that when the testing is performed above 74 degrees Centigrade, obvious phenomenon of stick-slip will appear in the process of testing. That is to say the gliding is intermittent and not steady.

4. Actual Requirement

In actual package process, friction force often acts as both dragging and resistant force. Therefore, coefficient of friction must be effectively controlled within a proper range.

Coiled material for automatic package generally requires a smaller friction coefficient of inner layer and a moderate friction coefficient of outer layer. Friction coefficient of inner layer cannot be too small; otherwise it will cause displaced edging resulting from unstable packing piling during bag shaping. The outer friction coefficient being too big will cause tensile stain of material due to extreme resistance in the process of packaging. While it being too small will lead to dragging component slopping, which in turn may cause inaccuracy of electric eye tracing and cutting off positioning. The content of opening substance and smoothing substance of inner layer together with the stiffness and smoothness of the film will all influence the friction coefficient of complex film.

While studying friction coefficient of material, special attention should be paid to the influence of temperature. As stated above, different temperature will cause remarkable change of friction coefficient. Measured data should be obtained through actual testing. Friction coefficient of certain material may present obvious growth or reduction with the changing of temperature. It may also maintain data stability to some extent. Considering the fact that actual temperature of production line is difficult to be maintained around room temperature, friction coefficient of package material should not only be tested under normal atmospheric temperature, but also be investigated in actual operation temperature. The test can be completed through changing lab temperature (when the required temperature is close to room temperature) or by making use of the self-temperature controlling function of testing instrument. For example, Labthink can make the test easier by controlling testing temperature between room temperature and FPT-F199.9 °C .